The Spray Source FAQ's

Shipping

Yes. We offer international shipping. For more information on our shipping policy, click HERE.

It depends on where you are. Orders are processed in 1-2 days as long as all products are in-stock. All orders with mixed paint, expect 3-4 days for processing before shipping. For estimated shipping times, Please click Here for residential locations or Here for Commercial locations, otherwise it will tell you the estimated transit time at checkout.

We use UPS Ground for ALL hazmat shipping and USPS for non-hazardous (like magazines, shirts etc)

For calculated shipping rates: Shipping charges for your order will be calculated and displayed at checkout. This will also tell you the estimated delivery time. Please keep in mind our processing time.

If you haven't received your order within 10 days of receiving your shipping confirmation email, please contact us at sales@thespraysource.com with your name and order number, and we will look into it for you.

Sign in and track your order at thespraysource.com

Product

If a product is activated it is absolutely cannot go back into a gallon of unactivated paint otherwise it will activate the entire product and it will harden and go bad.

We always aim to make sure our customers love our products, but if you do need to return an order, we’re happy to help. Please read our Return Policy Here to confirm your products apply. If they do, please click our Chat in the bottom right of your screen, then click returns and follow the prompts.

The TDS Sheets are available on the TDS Tab on the product page, or to see them all click HERE.

Company

Bluemont, VA USA

The large majority of our products, we keep plenty in stock at all times. Some acceptions is: Linear Blocking Tools, Luma III products, Carpro Detailing products, and a few other items. That being said, in most cases these items still ship quickly, and will come in a separate shipment directly shipped to you.

The Spray Source is under new management. The Spray Source is owned by Thomas Nelson.

We ship non hazardous materials but paint related or hazardous we do not. Customer can check out on the website, if it allows them to check out we ship it and if it does not allow them to check out we do not ship it. The shipping fee depends on what they purchases as well as the address. We do not do shipping quotes, it's only the website does.

Alpha Pigments FAQs

Drop-In Pigments

Absolutely! Mixing pearls, pearl enhancers, or drop in pigments together can create awesome custom colors!

We HIGHLY reccomend testing small scale prior to using on a large project though as some colors do not work well together.

*Mixing 2 colorshifting pigments from oposite ends of the color spectrums can cancel each other out and create a "muddy" effect*

Yes! All of our pearl pigments are cosmetic grade. Our microflakes and liquid pigments ARE NOT COSMETIC GRADE.

This depends on your project and use case. Please check our "Mixing & Uses" tab on the product page of which ever pigment you are using.

Removable Automotive Paint Coatings, Automotive Traditianal Paint Coatings, Masterbatch pigmentation, Cosmetics, Plastic and rubber manufacturing, leather manufacturing, Screen Printing and Offset Printing, Architectural Coatings and much, much more.

Our RAL Drop-In Pigments come in 187 colors, ranging from vibrant Green Beige, Colza Yellow, to the classy Jet Black, and Platinum Grey.

Please browse through our RAL Drop-In Products to check all available colors.

Though our pigments looks good in any type of finishes, they are best in either Gloss, Matte, Satin, or Frosted finish

4 coats

Spray Cans

Plastic is fine as long as it's properly prepped and then sealed with the recommended epoxy primer.

2 Epoxy Primer Spray Cans, 2 Basecoat Spray Cans, and 2 Clearcoat Spray Cans for all wheels under 19".

For 19"+ wheels: Add 1 more spray can each.

Pearl Enhancers

This is a translucent pigment that comes in various colors fomulated to offer some of the deepest most custom colors possible. Pearl enhancers are designed to be mixed with our Alpha Pearls to create deep, vibrant, custom colors!

Our Pearl Enchancers come in 4 colors

-Yellow Pearl Enhancer

-Red Pearl Enhancer

-Green Pearl Enhancer

-Blue Pearl Enhancer

Microflakes

Micro Flake (MF) is a fine Hex cut flake at 0.2mm. MF can be sprayed out of a High Volume Low Pressure (HVLP) spray gun, conventional spray gun with a 1.3 nozzle setup or larger, and an Airbrush with a .35mm nozzle or larger.

MicroFlakes are a perfect way to accent a base color, pearl or colorshift finish.

Micro flakes / Metal flakes tend to cause texture. Topcoating and sometimes wetsanding & buffing is required.

We also always recommend microflakes to be glossed to get the full effect!

Custom Colors

A Colorshift, or Optically Variable, pearl changes color and hue based on viewing angle of the surface or medium it is in. They create vivid metallic effects just like a "chameleon" or "chrome illusion" paint job.

Luma III FAQs

LumaIII, Inc. will only ship to countries outside the USA as long as DHL provides us tracking updates through the destination country.

International shipping times are currently taking 7 to 15 business days.

International shipments using USPS (United States Postal Service) will only receive a single battery due to international shipping guide lines.

LumaIII, Inc. is NOT responsible for import taxes, duties, tariffs, or any other import taxes that may be later applied.

LumaIII,Inc. will NOT declare your product on the customs form as a gift, nor will we mark down the value of the product.

About Us

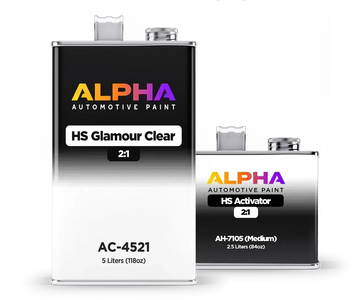

We sell complete paint kits for any size vehicle here Vehicle Paint Kits.

Just choose “Build Your Paint Kit” and select the size of your car. Next, select your project type and choose whether you’re doing a Full Color Change or External Panels Only. Lastly, select the temperature you’ll be spraying at. After that, you’ll have all the products needed to complete your project!

No, not at this time but we do offer DIY sample kits with a small amount of paint and speedshapes.

Any question?

If we still haven't answered your question, you can contact us HERE and we will get back to you as soon as possible.