Mazda USA Soul Red Crystal Metallic 46V | OEMatch Spray Can

Start typing to search the colors.

Mazda USA Soul Red Crystal Metallic 46V | OEMatch Spray Can

Description

Description

This is a "Tri-Stage" paint and requires the undercoat APU1459 to be sprayed underneath it for a precise OEM match.

Make: Mazda

Color Name: Soul Red Crystal Metallic

Color Code & Reference code: 46V

Years: 2017/

Models: Mazda3, Mazda6, Mazda CX-5, Mazda CX-30, Mazda MX-5 Miata

Color Type: Metallic

Description:

Experience the deep, dynamic brilliance of Mazda Soul Red Crystal Metallic 46V OEM Matching Automotive Paint. This signature Mazda color, featured on popular models like the Mazda3 and CX-5, delivers a precise factory color match with an intense, high-gloss finish. As a three-stage paint system, this color requires a U1459 undercoat to achieve its signature depth and clarity. The result is a vibrant red with a striking luminosity that enhances the body lines of any Mazda.

Designed for smooth application and professional-grade results, this paint is ideal for both expert refinishing professionals and DIY enthusiasts.

Features:

- OEM Matching Color: Exact match for Mazda Soul Red Crystal Metallic 46V with U1459 undercoat

-

Advanced Tricoat System: Three-stage paint process for deep, radiant red with unparalleled brilliance

- Easy Application: Suitable for professionals and DIY restorers alike

- Available in Multiple Sizes: Perfect for touch-ups or full vehicle repaints

- Professional Grade Formula: Ensures consistent color accuracy and superior performance

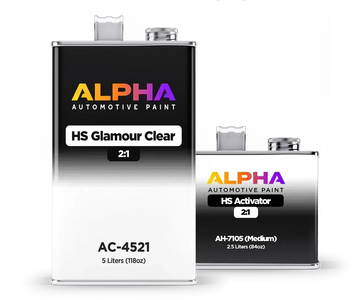

- Compatible with Clearcoats: Achieve enhanced gloss and protection when paired with Alpha Automotive Clearcoats

Restore or customize your Mazda with Mazda Soul Red Crystal Metallic 46V with U1459 undercoat OEM Matching Automotive Paint, delivering a factory-quality finish that embodies innovation, luxury, and modern sophistication.

* All OEMatch paint should be blended into surrounding panels. We do NOT guarantee butt-painted matches. We camera match to the supplied OEM color chips supplied by the manufacturer, but the manufacturer also has many variations depending on the vehicle, where it was painted, and when it was painted. Unfortunately there are slight variations on each individual assembly line and because of this we cannot guarantee matches on every vehicle, but can guarantee a blendable color.*

Application & Prep

Application & Prep

STEP 1 – CLEAN THE SURFACE

1 - Wash with soap and water, rinse, and dry completely.

2 - Degrease using wax and grease remover or isopropyl alcohol.

3 - Wipe dry with a clean, lint-free towel.

STEP 2 – SCUFF / SAND FOR ADHESION

If Raw Plastic / Polyurethane: Evenly scuff bare plastic or raw surfaces. These will also need to be adhesion promoted prior to paint.

If Good Condition OEM Paint: Sand smooth or glossy paint with P320-P400 grit sand paper or Scuff Pad until uniformly dull with no glossy areas.

If Surface Needs Bodywork or heavy scratches removed: Sand the damaged areas with 180 grit (feathered out into the panel) then do your bodywork. Finish in 220 Grit sanding. Then spot prime with high build primer - fading the primer out into the rest of the sanded panel covering the bodywork and any 220 grit scratches. (the good condition areas of the panel should have been sanded in 320-400 or scuff pad). Lastly, after the high build primer is dry and ready to be sanded (check tds for timeline), sand with 320-400 to match the rest of the panel.

After The above prep: Remove dust with compressed air or a clean microfiber towel.

STEP 3 – FINAL WIPE & TACK

1 - Wipe the surface again with isopropyl alcohol or wax and grease remover.

2 - Allow solvents to fully evaporate.

3 - Lightly wipe with a tack cloth immediately before spraying. Do not press hard. (optional but great step)

STEP 4 – SET UP YOUR SPRAY AREA

1 - Use a well-ventilated, well-lit area with good extraction fans

2 - Ideal conditions are 65–75°F (18–24°C) with 40–60% relative humidity.

3 - Keep the area free of open flames, sparks, or ignition sources.

4 - Wet the floor if your space allows to keep dust down

5 - Cover any items or areas in your space that you do not want to get overspray on

STEP 5 – PERSONAL PROTECTION

1 - Wear a respirator rated for organic or solvent vapors.

2 - Use nitrile gloves and safety goggles.

3 - Wear a paint suit

STEP 6 – SHAKE THE CAN

1 - Shake vigorously for 45–60 seconds.

2 - Invert the can several times while shaking to fully mix pigments and metallics.

STEP 7 – TEST SPRAY

ALWAYS DO A TEST SPRAY + SPRAY OUT CARD IF DOING OEM SPOT JOBS

1 - Spray on cardboard or a scrap panel.

2 - Confirm even spray pattern, correct color, and proper atomization.

3 - Adjust the spray can's nozzle to match your spray style or surface.

4 - If the can is not operating correctly, remove the cap completely, reseat it on the can, and twise the entire nozzle 360 degrees. Since our cans are made to order, sometimes there is slight paint build up and reseating the nozzle corrects this.

STEP 8 – SPRAYING TECHNIQUE

1 - Hold the can 5–6 inches from the surface.

2 - Keep the can perpendicular, 90 degrees to the panel at all times.

3 - Move at a steady speed using smooth, even passes. You are looking for medium wet coats NOT super wet, pooling coats.

4 - Overlap each pass by 50 percent.

STEP 9 – TRIGGER CONTROL

1 - Begin moving before pulling the trigger. Start off of the panel then move onto the panel. This avoids build up on edges.

2 - Fully depress the trigger while spraying.

3 - Release the trigger completely at the end of each pass.

4 - Stop spraying after clearing the panel edge by an inch.

STEP 10 – COATS & FLASH TIMES

1k Primer/Sealer

1 - Spray a medium wet coat on the entire panel (if not blending oem paint) to achieve a 75% coverage. This fills in the sanding scratches as well as gives a uniform , required ground coat color for the next steps.

2- Allow to flash dry for 5-15 minutes. Time depends on the product and environment.

3 - Apply the second medium-wet coat to achieve full coverage

4 - Allow to dry for 30 minutes or until the wet look fades so a dull, even finish and is completely dry to the touch.

GROUNDCOATS or SOLID COLORS (BEFORE MIDCOATS IF APPLICABLE)

This is for our Base Black, OEM Undercoats or solid colored basecoats. Not all projects require this step.

1 - Apply the first medium-wet coat at approximately 75 percent coverage.

2 - Allow to flash 5-15 minutes or until the wet look fades so a dull, even finish. Time depends on the product and environment.

3 - Apply the second medium-wet coat to achieve full coverage

4 - Allow to flash 5-15 minutes or until the wet look fades so a dull, even finish. Time depends on the product and environment.

5 - Apply a Third medium wet coat if the color is not 100% covered and even at this point. This will vary based on the color and product being sprayed.

4 - Flash another 15-30 minutes. Until the surface is even, dull, an dry to the touch.

MIDCOAT , CUSTOM COLORS , OR METALLIC/ PEARL OEM

This is for coverage over required groundcoats , not "ghost effect"

1 - Apply medium coats over the required groundcoat for your color.

2 - Flash 5–15 minutes between coats or until tack-free.

3 - Apply additional coats until the desired color depth is achieved. Most custom and oem colors require 2-4 medium coats - check color description or compare to existing oem panels

4 - Apply 1 light "control" coat to make sure all of the pearl or metallic is even and not splotchy or "tiger striped"

5 - Wait 30 mins or 15 mins after the surface is completely dull and dry to the touch before moving on to topcoat step.

EFFECT PEARL / COLORSHIFT COAT

This is for effect over light groundcoats (not for coverage)

1 - Apply one light effect coat at approximately 25 percent coverage.

2 - Allow 5-15mins for the coat to flash before adding another light coat (if you want to add more effect)

Repeat as many times to your preference of effect and coverage.

3 - Wait 30 mins or 15 mins after the surface is completely dull and dry to the touch before moving on to topcoat step.

STEP 11 – CLEANUP & STORAGE

CAP CLEARING

1 - Turn the can upside down after spraying.

2 - Spray until only clear propellant comes out.

3 - This clears paint from the valve and prevents clogging.

NOZZLE CARE

1 - Remove the spray nozzle after use.

2 - Wipe clean with solvent.

3 - Do not soak the nozzle in solvent.

STORAGE

1 - Store cans upright in a cool, dry place.

2 - Keep away from direct sunlight.

3 - Avoid freezing conditions.

4 - Do not store above 120°F (49°C).

QUICK TROUBLESHOOTING

1 - Dry or rough texture means the can is too far away or moving too fast.

2 - Runs or sags mean the can is too close or moving too slowly.

3 - Continue to shake and agitate the can between coats- Repeat step 6

4 - If ever unsure the color is 100% covered (and you are going for coverage) - one extra coat is always a good idea.

Frequent Questions

Do I Need 2k Clearcoat Topcoat?

Do I Need The Gray 1k Sealer?

Do I Need High Build Primer?

What Color Primer/Sealer Is Recommended?

Mazda USA Soul Red Crystal Metallic 46V | OEMatch Spray Can

$39.99 USD

Mazda USA Soul Red Crystal Metallic 46V | OEMatch Spray Can

$39.99 USD