Mastering Automotive Finishes with Linear Blocking Tools Sanding Blocks

If you're tackling automotive paint or body projects, choosing the right tools can be a real challenge. It's not uncommon for people to struggle with finding the best tools for those final touches, especially when dealing with Linear Blocking Tools Sanding Blocks. This is particularly true for contoured surfaces.

These tools enable both experienced professionals and DIY enthusiasts to achieve stunning results. The variety of Linear Blocking Tools Sanding Blocks available might seem a bit much at first, but it doesn't need to be.

This guide will break down everything you need to know about Linear Blocking Tools Sanding Blocks, making your next project a masterpiece. With the proper tools, anyone can make something go from average to beautiful again.

Table Of Contents:

- Understanding Linear Blocking Tools

- Semi Flex Blocks

- Techniques for Using Linear Blocking Tools

- Real-World Applications and Tips

- Choosing Between Wet and Dry Sanding

- Advanced Techniques and When to Use Them

- Sanding Block Comparison Table

- Frequently Asked Questions (FAQs)

- Conclusion

Understanding Linear Blocking Tools

Linear blocking tools are essential for anyone involved in car restoration, customization, or collision repair. Their primary purpose is to achieve perfect alignment and incredibly smooth surfaces. With all of the Linear Blocks we recommend using the Linear Sand Paper, whether you're dry sanding body filler or primer or wet sanding clear coat.

What sets these tools apart is their unique design and adaptability. They are available in rigid, semi-flex, and ultra-flex forms, making them suitable for various panel shapes and project requirements.

These tools are mainly used for refining bodywork, applying primer, and final polishing stages. Selecting the correct tool, combined with proper technique, effectively eliminates imperfections such as uneven body filler or minor dents.

The Rigid Block

Rigid blocks are perfect for use on flat surfaces. They offer maximum control for removing excess filler and creating consistent shapes.

This option is great for projects like restorations, where metal shaping may require additional refining. Applying linear high build dtm epoxy primer with a rigid block can create a solid foundation.

An online forum member on a shared build post detailed their 'rod' project, using rigid sanding blocks. So this experience offers added insights into real-world applications.

Flex and UltraFlex Blocks: A Breakdown

Flex and UltraFlex blocks are specifically designed to handle curved surfaces. Since car panels frequently have varying degrees of curvature, this type of block is indispensable.

Their flexibility ensures the block maintains even contact with the panel, addressing both low and high spots in bodywork. For instance, 18' Linear Blocks provide excellent flexibility for more moderate curves.

Consider using an Ultra Flex Block on a curved panel like a fender on a Volkswagen Bug; a Flex block ensures even extremely curve panels can get the texture flattened out. Proper tools like these also can assist with a perfect finish, similar to panel painting on a classic car project.

Choosing the Right Size and Flexibility

The size of the block directly impacts its flexibility and the area it covers. Longer blocks, such as the 32' Linear Blocks, are inherently more flexible.

These longer sizes provide more bend, making them ideal for working on panels with significant curves, like large fenders or rounded body lines. Consider using different dry sand paper grits with these which we sell in a complete bundle or in an individual grid.

Shorter blocks offer less flexibility, providing greater control on smaller or less curvy surfaces. The degree of flexibility from one block to another can significantly impact the effectiveness of a linear blocking tool, so it's crucial to choose the right amount of flex for the specific part of the vehicle.

Semi Flex Blocks

Semi Flex blocks represent a middle ground between rigid and UltraFlex options. They allow for slight contouring while maintaining a stable sanding surface.

These blocks are great for panels with mild curves. SemiFlex Blocks would help flatten the texture while keeping the panels curve.

Consider projects with moderate curves on body panels, such as many Camaro restorations. Their hoods often require careful sanding to preserve the original factory appearance, and a SemiFlex block can be the perfect tool for this.

Techniques for Using Linear Blocking Tools

Using these tools correctly can transform an average finish into a professional one. Begin with a cross-hatch pattern to ensure even surface work, effectively eliminating high and low spots.

For high-build primer, which involves substantial material, more shaping for alignment is required. Start with coarser grit sandpaper and if a complex restoration project with large curves requires it, an Ultraflex with aggressive cuts using 150g or 180g dry paper may be necessary. Once the panel has shape, transition to less aggressive cutting paper and a straighter, less flexible block, even up to a rigid one, to prevent ripples while leveling and sanding out those initial cuts.

Wet sanding with Linear Blocking Tools can achieve an exceptionally smooth finish especially when wet sanding before polishing a clear coat. This process involves keeping both the sandpaper and the surface wet, reducing friction, minimizing dust to provide a clearer view of the cutting area, and leaving fewer sanding marks.

Real-World Applications and Tips

Whether you're undertaking a complete restoration or addressing minor collision damage, this method can significantly improve your results. For example, using an 18' Ultra Flex Block allows for consistent shaping around a wheel arch.

Imagine working on the long, curvy fender of a vintage sports car. Choosing an UltraFlex block will allow you to block even curvy panels smooth as well as the flatter panels. This will allow you to create a uniform finish on the entire project much faster and easier than other blocks would allow in the past.

Maintenance and Care for Linear Blocking Tools

To maintain the effectiveness of your Linear Blocking Tools over the years, proper care will keep your blocks sanding flat and easy for years to come. Clean your blocks as per this video by removing all dirt and buildup after each use on your auto project.

Should you encounter any issues with your blocks, Linear Blocking Tool's contact form is available for support. When reaching out, provide detailed information and specific questions to receive the most effective assistance. Linear Blocks have a limited lifetime warranty for as long as you are cleaning them properly and maintaining them it would last you a lifetime.

Choosing Between Wet and Dry Sanding

The decision to use wet or dry sanding depends on the materials involved, the condition of the surface, and the current stage of the process.

Dry sanding is effective for quickly removing material, while wet sanding offers less aggressive cuts. For tasks that require a high-quality finish and greater control over material removal, wet sanding is superior. For body working and block sanding primer we recommend dry sanding with lower grits sand paper such as 80g to 320g. For finishing, we recommend wet sanding the clear coat before polishing. Grits that you would use for this would be 800g to 3000g.

Beginner's Guide to Selecting Your First Linear Blocking Tool Set

For those new to automotive painting, the entire process and the variety of options can feel overwhelming. With each new project, selecting tools with confidence and mastering their use will become easier.

A practical tip for beginners is to select sets that provide a range of options. The Linear Blocking Tools Starter Set, for example, includes both UltraFlex and SemiFlex blocks, allowing you to adapt your blocking technique based on the flatness or curvature of the car project. We also recommend getting the sand paper bundles to go along with the Sanding Block Set.

Also adding in some individual blocks could benefit things as well.

Advanced Techniques and When to Use Them

To elevate your skills, advanced blocking techniques allow for real-time adjustments to accommodate the intricacies of car bodies. You can learn techniques on our Youtube Channel here.

Using an UltraFlex block on highly curved areas, then transitioning to a Semi Flex block once the surface is smoother, grants you complete control over the shaping of the bodywork. If using a product like Linear High Build DTM Epoxy Primer, using the correct steps is critical.

Sanding Block Comparison Table

Here’s a quick reference comparing the block types:

| Block Type | Flexibility | Ideal Use Case | Available Sizes |

|---|---|---|---|

| Rigid | None | Flat surfaces, initial shaping | 8', 12', 18', 24', 32' |

| SemiFlex | Moderate | Gentle curves, transition areas | 8', 12', 18', 24', 32' |

| UltraFlex | High | Highly curved surfaces, complex shapes | 8', 12', 18', 24', 32' |

Using the right type of linear blocks can assist the user. Some may be learning via free tutorials.

Frequently Asked Questions (FAQs)

What is the advantage of using Linear Blocking Tools over regular sanding blocks?

Linear Blocking Tools are designed with varying degrees of flexibility. Permitting them to conform to the different shapes of car panels for a more even and smooth finish. Also with them being made with Poly Carbonate it has a solid base which helps sand flatter compared to foam.

Can I use Linear Blocking Tools for both wet and dry sanding?

Yes, Linear Blocking Tools can be used for both wet and dry sanding. Make sure to adjust the sandpaper grit and techniques according to the job details.

How do I clean and maintain my Linear Blocking Tools?

After use, be sure to clean them from dust, and keep them safe. You can follow our cleaning video here.

Are Linear Blocking Tools suitable for beginners?

Absolutely, and while there are lots of blocks and methods to start with, these can for sure assist anyone at any level. Start with a starter set.

The ability to match to curves and know when a flat section has an issue is not magic, but rather comes from testing things out and experience. Look into potential wet sanding/buffing tips that many share.

Conclusion

Linear Blocking Tools Sanding Blocks are essential for those who restore, customize, or repair car bodies after collisions. Mastering the use of these adaptable tools can boost your confidence in tackling auto body repairs.

By choosing and using Linear Blocking Tools properly, you can see a truly transformative effect on your projects.

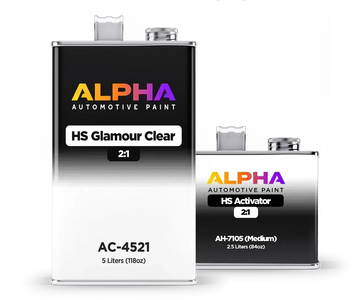

Always start with a good base of products, like the paint products that are included in our vehicle paint kits. As well as using a great quality body fillers like our TrueFill, you'll be able to create a better finish, quicker as well as a higher quality finish for many years to come. Using the correct blocks and the correct sanding paper grits with each step will be key to saving time while also getting the best finish possible.

Discover our Alpha Automotive Paint products for your next project.

Follow us on Instagram and Tommy Knows Paint for more projects and tips.