PERUVIAN WHITE PEARL OVER WICKED WHITE | AUTOFLEX COATINGS | PEELABLE PAINT | MERCEDES

This Mercedes is looking sleek with Peruvian White Pearl. In addition to using our Wicked White drop-in pigment and our Peruvian White pearl, this ride is topped with a satin finish. The result looks clean and smooth.

This Mercedes is looking sleek with Peruvian White Pearl. In addition to using our Wicked White drop-in pigment and our Peruvian White pearl, this ride is topped with a satin finish. The result looks clean and smooth.

Installer: Rose City Dip LLC

Coating: Autoflex Coatings

What You Need for the Peruvian White Pearl Look

Pigments needed for this look:

- Wicked White basecoat

- Peruvian White solid pearl (50g per sprayable gallon)

- Satin finish

Like all of our pearl pigments, Peruvian White Pearls can be used in Alpha Automotive Paint and many other systems. This also works in epoxy resin and other creative projects.

This color is available in Automotive Paint, Aerosol Spray Cans, and Vehicle Paint Kits. Choose the format that fits your tools and project size.

Why Peruvian White Pearl Looks So Clean

Peruvian White Pearl is a solid pearl that adds depth without heavy sparkle.

The finish stays bright, but it still has a soft pearl glow.

That balance helps body lines look sharp in shade and sunlight.

A satin topcoat can make the look even more modern and refined.

Surface Prep That Improves Final Clarity

Clean prep makes a bigger difference than most people expect.

Small scratches can show through lighter colors after clearing.

Sand panels evenly to prevent patchy texture in reflections.

Use consistent grit steps to avoid deep sanding marks.

Blow off dust before wiping with wax and grease remover.

Use clean towels to avoid dragging dirt across the surface.

Mask edges tightly to reduce peeling during unmasking.

Seal bare spots so the base lays down evenly.

Spray Gun Setup for Even Coverage

Set air pressure to match your gun and product sheet.

Test spray on paper to confirm a smooth fan pattern.

Adjust the fan wide enough for consistent overlap.

Keep the gun distance steady across each panel.

Move at a consistent pace during each pass.

Overlap each pass evenly to reduce striping.

Strain mixed material to prevent nozzle clogs.

Stir often during the job to keep pigments suspended.

Flash Times and Working Conditions

Temperature changes flash time and overall flow.

High humidity can slow drying and dull the surface.

Good airflow helps solvents escape between coats.

Use proper lighting to spot dry spray and uneven areas.

Allow each coat to reach tack before recoating.

Rushing can trap solvents under the clear layer.

Trapped solvent may cause texture later.

Color Control Without Extra Recoats

Start with a uniform white base for predictable brightness.

Keep coats medium wet, not heavy and flooded.

Heavy coats can run and create mottled appearance.

Light coats can look dry and grainy.

Find a smooth balance using test panels first.

Use the same technique on every panel.

Panel to panel consistency matters most on light finishes.

Clearcoat Choices and Care

Clearcoat selection affects gloss, depth, and durability.

Gloss clear highlights reflections and sharp body lines.

Satin clear softens reflections for a modern look.

Both finishes need full cure before washing.

Use mild soap and soft microfiber towels.

Avoid harsh brushes and abrasive cleaners.

Consider a ceramic coating after curing.

Ceramic protection can help reduce staining and swirl marks.

Quick Troubleshooting Guide

Dry spray often comes from low material flow or fast passes.

Increase flow slightly or slow down your movement.

Striping can come from uneven overlap.

Correct overlap and keep the gun distance consistent.

Orange peel often comes from wrong reducer choice.

Adjust reducer speed for your temperature range.

Dust nibs are common in home garages.

Use tack cloths and keep air moving cleanly.

Extra Notes for First-Time Painters

Do a full mock spray on a scrap panel first.

Practice starting and stopping off the panel edge.

Keep trigger control smooth through each pass.

Plan your route around the vehicle before spraying.

Work from roof to sides, then lower panels.

That order helps reduce dirt landing on fresh coats.

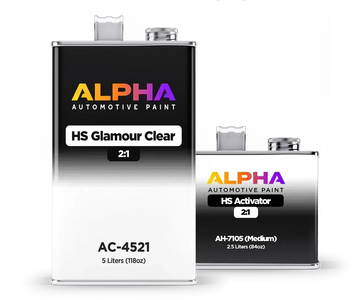

Alpha Basecoat System Used on This Project

This project uses an Alpha Custom Color basecoat with a binder made for pigment control.

The binder supports UV resistance and strong pearl suspension.

The basecoat mixes 1:1 with an AR-30xx reducer for smooth application.

Consistent mixing helps the color lay down evenly across panels.

For prep and adhesion, use AP-7541 DTM Primer-Sealer. It provides fast drying and excellent flexibility.

For protection, use AC-4521 HS Glamour Clearcoat. It adds durability and UV protection.

How to Mix Peruvian White Pearl

Use a clean mixing cup and measure accurately.

Add the pearl at the recommended rate for your sprayable volume.

For this look, use 50g per sprayable gallon.

Stir thoroughly, then strain before spraying.

Good strainers reduce clumps and improve flow.

Finish Options That Change the Final Look

Clearcoat choice affects how Peruvian White Pearl reads in light.

Gloss clearcoat increases depth and sharp reflections.

Satin clearcoat softens the highlight and looks understated.

Both can look premium when the spray pattern stays consistent.

Project Step-by-Step Guide

- Complete prep, body work, primer, and sanding using our video tutorials.

- Block-sand exterior panels with 320 grit sandpaper.

- Scuff jambs and tight areas using a red scuff pad.

- Blow off dust outside and wipe down with wax and grease remover.

- If needed, paint jambs and the engine bay first.

- Wait 24 hours before moving to the exterior panels.

- Re-mask and wipe down using anti-static wax and grease remover.

- Spray one medium wet coat of AP-7541 DTM Primer-Sealer at 4:1:1.

- Use a 1.4 mm needle spray gun for the sealer coat.

- After the sealer is dry to the touch, wait at least one hour.

- Mix and spray your basecoat color over the sealer.

- Most colors need 2 to 4 coats for coverage and effect.

- Wait until the basecoat is dry to the touch before recoating.

- After the final basecoat is dry, wait 45 minutes.

- Spray 2 to 3 coats of AC-4521 HS Glamour Clearcoat at 2:1.

- Recoat when the previous coat feels tacky to a light touch.

- Let the finish cure for 12 hours in a warm ventilated area.

- If wet sanding and buffing, keep it masked for that process.

- Otherwise unmask, assemble, and enjoy your finished project.

Common Tips for Even Pearl Coverage

Keep the gun distance consistent across every panel.

Overlap each pass evenly for uniform pearl layout.

Maintain steady speed to avoid striping.

Spray test panels before you commit to the full vehicle.

These steps help the color look even from every angle.

Follow us on Instagram and Tommy Knows Paint for more projects and tips.